mining

Typical Material Grade Used but not Limited to:

C93800

C86300

C95400

C95500

C93700

C93200

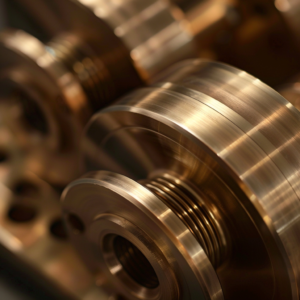

Bronze plays a crucial role in mining equipment due to its strength, durability, and excellent resistance to wear and corrosion. Mining equipment operates in harsh, abrasive environments, where parts are exposed to heavy loads, impact, and aggressive substances like dust, dirt, water, and chemicals. Bronze, with its unique properties, is ideal for several key components in mining machinery. Here’s how bronze is used in mining equipment:

- Wear Resistance: Mining equipment often involves moving parts that experience heavy friction. Bronze is widely used in bushings and bearings, where it helps reduce wear and tear due to its natural lubricating properties. This is especially important in parts like crushers, mills, and conveyors, which experience constant movement.

- Longevity: Bronze bushings last longer than many other materials, reducing the frequency of part replacements and increasing the overall lifespan of mining machinery.

- Corrosion Resistance: Mining often deals with water containing various minerals and chemicals. Bronze, particularly alloys like brass (copper-zinc alloys), is highly resistant to corrosion caused by such elements. This makes it ideal for components in centrifugal pumps, which are used in mineral extraction and dewatering processes.

- Strength: The toughness of bronze ensures that pumps and their components can handle the intense pressure and impact that often occur during mining operations.

- Durability and Toughness: Mining equipment like excavators, trucks, and processing plants rely on gears to transmit power. Bronze gears are favored for their high strength, toughness, and resistance to wear, ensuring efficient power transmission and longevity of the gear systems.

- Reduced Friction: The self-lubricating nature of bronze helps reduce friction between gear teeth, preventing overheating and improving the performance and reliability of gearboxes in heavy-duty mining applications.

- Corrosion Resistance and Strength: Many mining machines rely on hydraulic systems for lifting, digging, and transporting materials. Bronze components in hydraulic pumps and valves offer high resistance to corrosion and are able to withstand the high pressures involved in these systems.

- Minimal Maintenance: Since hydraulic systems in mining are constantly subjected to high stresses and harsh conditions, the durability of bronze minimizes the need for frequent maintenance or replacements.

- Protection against Abrasive Wear: In mining, equipment is often exposed to abrasive materials like rocks and gravel. Bronze wear plates can be used in high-wear areas to protect the underlying structure of the equipment, reducing the frequency of repairs and extending the life of the machinery.

- Shock Absorption: Bronze can absorb shock and impact, helping to protect the machinery from sudden forces that occur during operations like drilling, crushing, or transporting materials.

- Resilience: Bronze is often used for tools and parts that are subjected to impact forces, such as drilling bits and hammers. The alloy’s ability to withstand heavy impacts without cracking or deforming makes it valuable in mining operations.

- Enhanced Performance: Components made from bronze provide superior performance in extreme conditions, offering a better combination of strength and corrosion resistance compared to other materials.

- Conductivity: Bronze alloys (like copper-nickel) are used in mining equipment where electrical components are essential, such as for grounding, wiring, and connectors. Their electrical conductivity and resistance to corrosion ensure reliable performance in mining environments.

In mining equipment, bronze’s role is primarily focused on providing durability, wear resistance, corrosion resistance, and strength in key components that face harsh conditions, such as bearings, bushings, gears, hydraulic systems, and wear-resistant parts. The material’s self-lubricating nature and ability to handle the stress of heavy-duty operations make it indispensable for the longevity and efficiency of mining machinery.