Quality Control

At Advance Bronze Inc., our commitment to quality is upheld through systematic and meticulous inspection procedures, ensuring that all shipped products meet stringent standards for material integrity and craftsmanship. Utilizing our state-of-the-art Coordinate Measurement Machine (CMM), we meticulously inspect tight tolerance parts with precision up to.001″.

We operate under a robust quality management system compliant with AS9100/ISO 9001 standards. Upon request, we provide comprehensive chemical and physical analysis test reports. Each batch of material maintains full traceability with unique and repeating heat numbers, verified using an optical emission spectrometer.

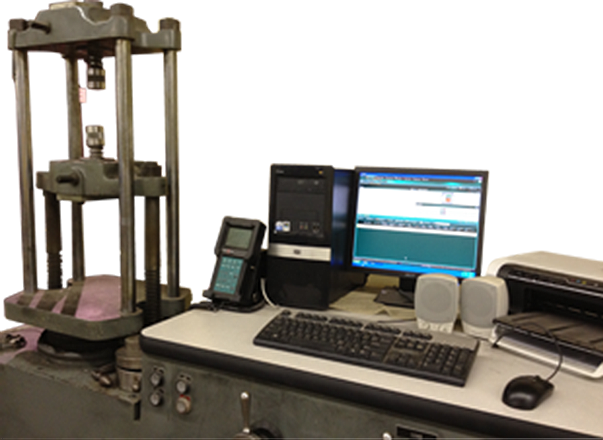

For Non-Destructive Testing (NDT) needs such as X-Ray or dye penetrant testing, we collaborate with NADCAP-certified vendors. We also offer Brinell hardness testing, pressure testing, mechanical or compression testing as per ASTM requirements or customer specifications.

To meet specific customer requirements for serial numbers and special identification marks, our advanced laser engraving capabilities ensure clean and identifiable marking on products.

At Advance Bronze Inc., our dedication to quality assurance and compliance allows us to consistently deliver products that meet the highest industry standards and exceed customer expectations.